resizing!

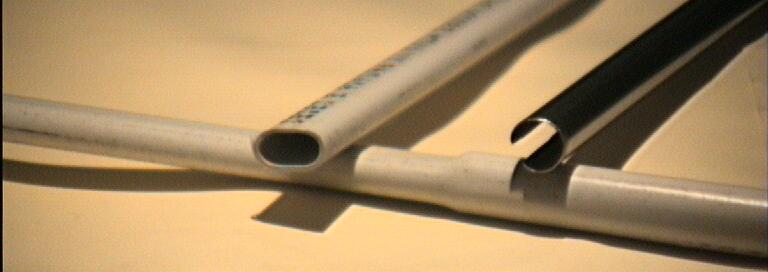

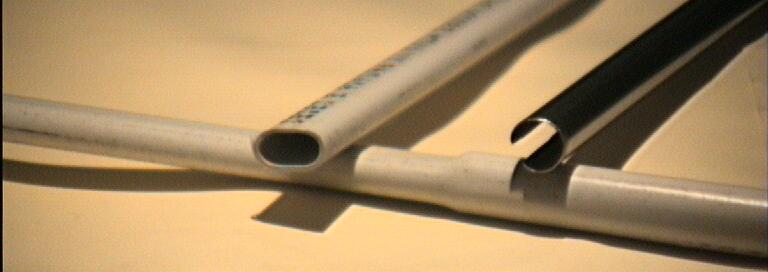

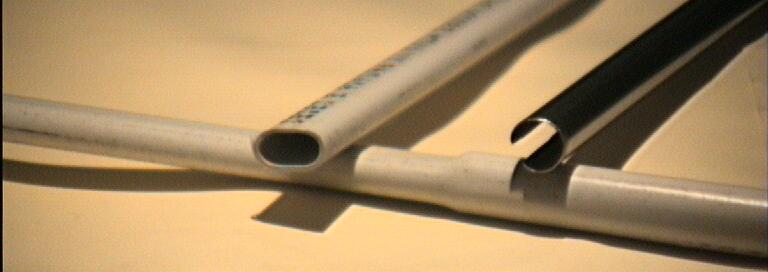

Top left : Original oval tubing.

Top right full size 16 mm OD mandrel.

Underneath:PVC sleeve 17.5 mm OD half resized.

Resizing:

--------

The operation of resizing is done with a Heat gun.

Now if you haven't done it before.

There is a way to do it right, and plenty to do it wrong.

So i will try to explain it to you.

For a start don't worry about making a mistake.

You can always redo it "IF" you do not heat the PVC to a burn.

A bit of experience will teach you when that moment is close.

As a rule of thumb, do not stay too close and at the same place, for too long.

Keep moving your heat gun up, down, and around.

You can resize it again and again without a problem.

So don't be worried if it doesn't work the first time.

"Practice makes perfect."

Do not try to make a slider 1 m long at first!

A small insert to start with is good!

When you do small inserts, have them a bit longer than necessary

So as to have enough to hang on.(you need something to push on, without burning your hand).

When you do long tubes you'll do them one half at the time, so they can be cut exactly.

Get your gear organized.

You need a clean dry rag and another wet one, but not dripping.

Start by securing your mandrel in a vice or something sturdy.

Now you have to warm up the mandrel by going up and down the shaft.

Otherwise the tube will cool off too quickly when you push it along as it warms up.

Specially at the beggining of the process.

After a lill while Get the end of the oval PVC tubing close to the mouth of the mandrel.

And start warming it up as well. By rotating it in the hot air flow.

"Just the end" Otherwise it becomes a wet noodle,

and you won't be able to push further up.

When that happen to you. Just let it cool a bit by moving the gun off the PVC.(move it on the mandrel!)

Now as the end of the PVC warms up (remenber to keep the gun moving, mandrel_> tube_> mandrel_> tube..etc.. )

check the softening after 30 sec or so by pressing the end on your bench .

when it start to give and become real weak slide the end on the mouth of your mandrel

and start pushing it slowly, while rotating at the same time.

Keep moving your gun all around the area of the tube you are working on.(over and underneath as well! )

You will notice that as the tube rezise along the mandrel it stops after 20 mm or so

This is because it cools down on the mandrel.

And also because you heated up only a bit at a time as i told you ! Right !

you simply have to repeat the operation 20 mm at a time until you reach about 30 or 40 cm

This is when you hit the wall..

The friction forces on the mandrel makes it nearly impossible to keep pushing.

No worries! there is a way out !

In the mean time keep your heat gun moving around and about not too close.

Grab your "dry" rag and slide it on the tube to equalize any bumps and wrinkles.

That may have been created in the process by any unequal heating of the tube.

A little bit of extra heat on them will help you do so.

When your'e happy stop the heat gun grab the "wet" one and do the same.

this will harden the PVC.

Congratulation !. you just created your first insert.

for long tubes once done half of it, just turn it around and do the other end.

Until you reach a bit over the end of the first pass.

Smooth it up, and it will look just like you did it in one pass.

Note: the tube has some kind of memory , since you stretched it up.

Do not warm it up outside of the mandrel. Or it will tend to get oval again.

if you want to retouch it. Slide it over and do it then.