Slicing and reducing!

Curtain rods mandrels !

----------

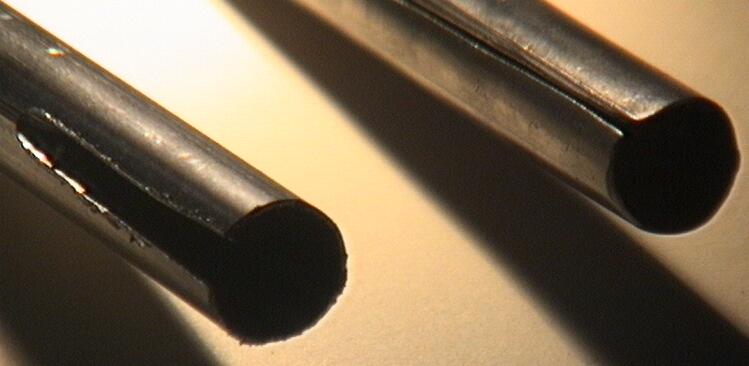

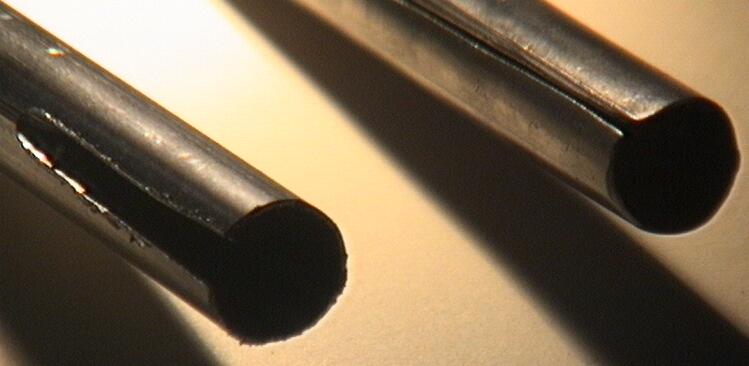

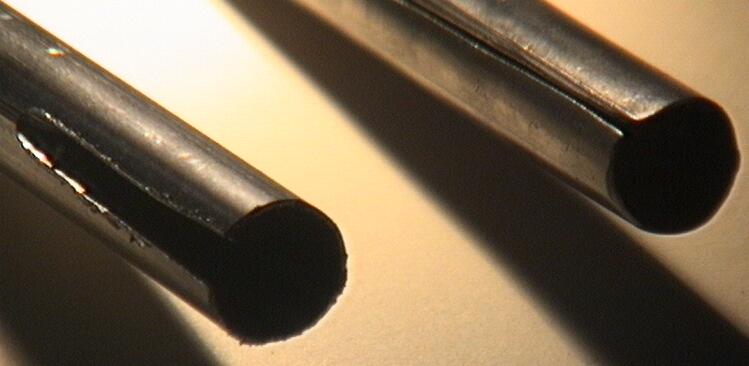

From left to right:

1) curtain rod stripped unreduced .

( note: this is only at the start of the slicing phase and in a raw state. It needs to be polished.)

Once polished and as is (unreduced). It would be suitable to form the 17.5 mm tight fit sleeves.

2) curtain rod mandrel in the finished state and with a reduced diameter for the 17 mm loose fit (sliders)

Slicing phase:

--------------

The slicing phase is a "pain" to do properly but necessary for 2 reasons:

1) Slicing the rod give it a bit of spring Which is important to be able to release the tube once resized.

2: It enables you to resize the mandrel to a smaller diameter. The only way to create sliding tubes.

Tips:

-----

Wear goggles and make sure you don't have any flammable liquid or material in the way of the sparks!

Secure your rod into a vice or at a good height so as to be comfortable doing the job at hand.

Use a "thin" metal cutting disk on your angle grinder.

Start cutting using the welding joint on the rod as a cutting guide (darker surface)

Slice just a bit at a time (1 cm or so) checking your work as you go.

Make sure you are going straight. as sparks hides the cutting.

It may take a couple minutes more to do a good job.

But the mandrel once done is forever..

So be patient !

Reducing:

---------

In order to resize the PVC to 17.0 mm (launch tubes sliders)

You need to resize the mandrel to +- 16.0 mm.

This operation is done by taking the slack created by the previous cutting.

In order to do so you need to squeeze the tube along its lenght,

In a way that keeps it as smooth and regular as possible.

You can use use either a vice or a pair of pliers with a suitable preform.

A piece of previously resized PVC cut in half ( )

To which you add a bit of curtain rod cut the same would be suitable.

Just squeeze moderatly along the lenght until the previoulsy "cut and polished"

tube is almost close along the cut see the upper right picture.

look at it from one end . and re-squeeze any problem area.

you should make sure the final result is round.

you may have to squeeze or lightly hammer at 90 deg to get rid of the ovalisation.

That's it.

Now give it a light oiling to keep it from rusting

and store it in a protective tube of sort for storage.

(rolled in oiled paper and inserted in a tube is quite good.

wipe it of before using it.

and wash your insert when done with soap

and clean them with metho or acetone before gluing them.